ALTEN introduces its Smart Factory 4.0 program to make the aerospace industry greener, safer and more efficient

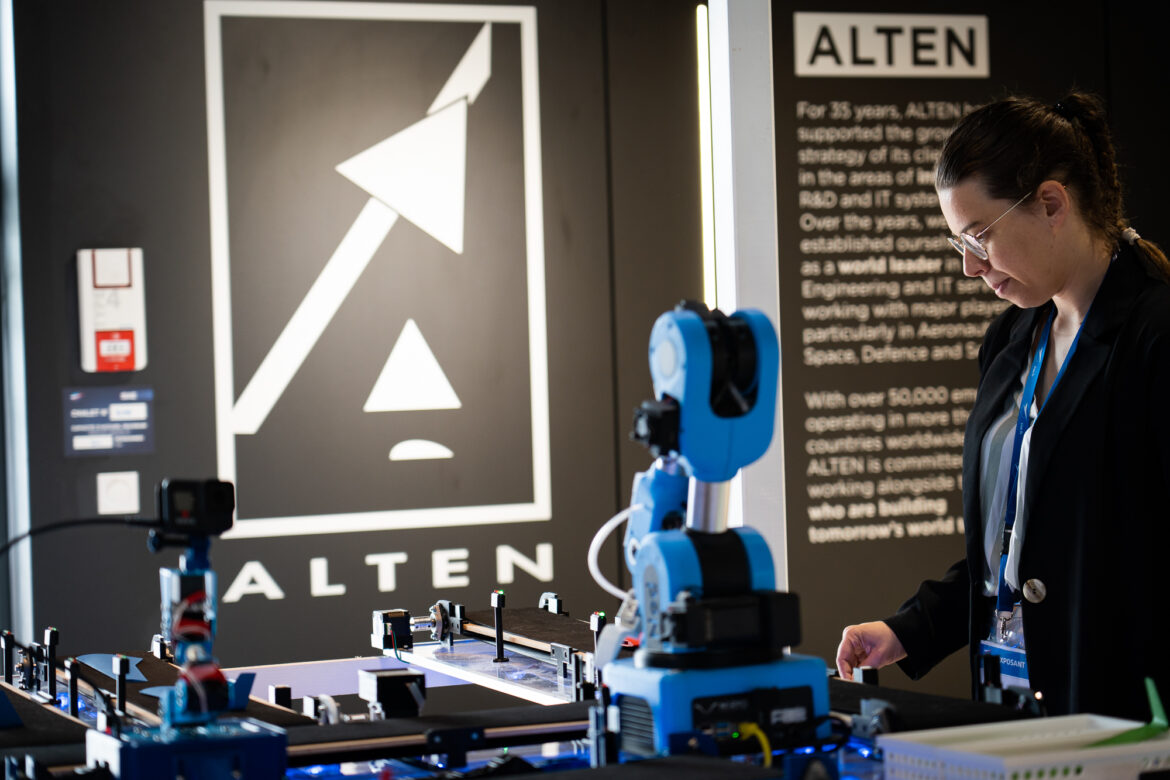

At the Paris Air Show 2023, ALTEN will be showcasing its innovative Factory 4.0 expertise to work with customers in imagining the air and space sector of tomorrow and shaping the future of this industry. The Smart Factory 4.0 roadmap, which is the result of ALTEN’s research and innovation, places the advances of digital technologies at the service of a more sustainable, low-carbon world.

Pierre Bonhomme, Executive Director of ALTEN

“The needs of the aerospace industry have changed profoundly since the last Paris Air Show in 2019. As the post-Covid recovery has led to a sharp increase in activity, the industry must be able to respond sustainably and efficiently. ALTEN supports its customers in integrating the latest technological advances across their entire value chain, thereby developing new production models.”

The ambition of Factory 4.0 is to increase industrial performance by combining human and artificial intelligence, in the service of a sustainable world. With the “Smart Factory 4.0” program, ALTEN explores the founding subjects of Industry 4.0, centered on the transformation of industrial sites: IoT, the digital twin, AI, augmented reality, robotics, industrial IT systems and cybersecurity. The various technological building blocks of Industry 4.0 are examined through concrete case studies, which then illustrate their value propositions.

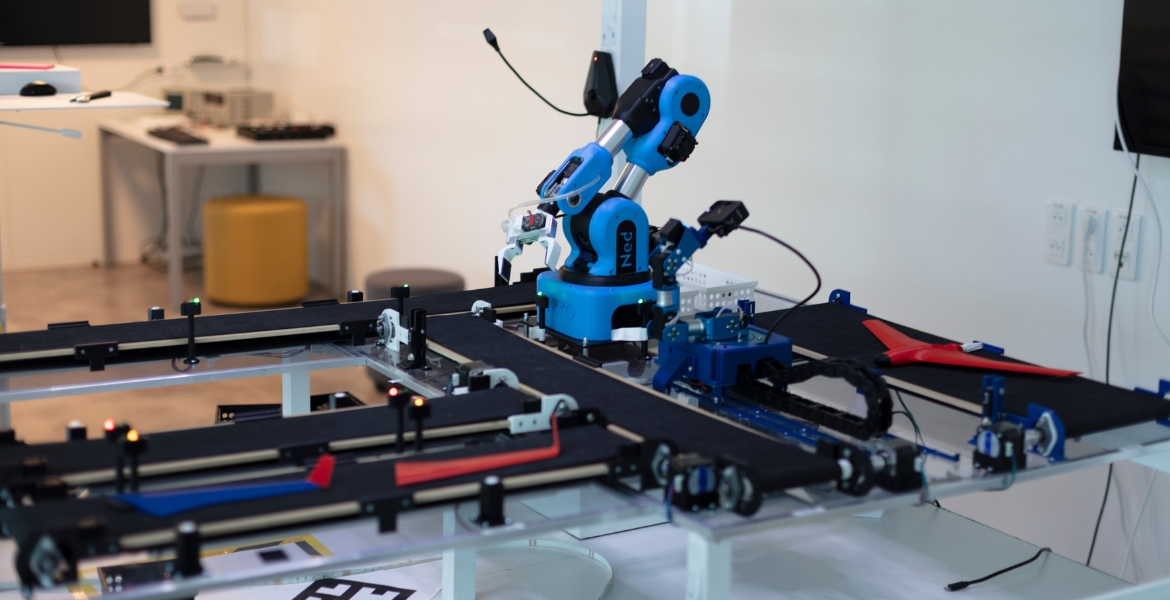

Mini-Plant 4.0: Artificial Intelligence for Human Use

The ALTEN Labs, dedicated to the Group’s research and innovation, carry out projects combining the energetic efficiency of digital systems, the eco-design of sustainable mobility, and the flexibility and resilience of factories in the Industry 4.0 era. All these projects are built around the human factor, a theme that is present in the application of Digital Twin technology.

Research teams at the ALTEN Lab in Toulouse have built a real drone assembly plant combined with a digital twin. This platform, known as “Mini Plant 4.0”, can be used to analyze the impact of the plant’s various intelligences on industrial processes and efficiency. It can be remotely controlled in virtual reality.

Thanks to machine learning algorithms, large quantities of data collected from sensors can be monitored and processed, enabling alerts to be created for any deviations detected in real time (on-board AI), controlled time (plant AI in Edge Computing) and deferred time (enterprise AI in Cloud Computing). This helps prevent production problems and reduce the risk of accidents by supporting human decision-making, forecasting performance indicators and simulating results. Artificial intelligence (AI) and machine learning provide information on performance optimization, maintenance, emissions, and efficiency. These advancements are demonstrated by the Mini Plant 4.0.

“The factories of today must be more flexible, more communicative, and more efficient, while remaining at the service of the human being. The factory of the future is not just a range of new technologies, it’s a new way of working for the people who work there,” explains François Portier, Head of ALTEN’s Smart Factory 4.0 Research Program.

Factory 4.0 for sustainable mobility

Among the most noteworthy advances for the aerospace sector, sustainable mobility work involves the development of alternative energies as well as improved transport management.

- ALTEN is supporting a major aircraft manufacturer in the development of zero-carbon aircraft, which will replace kerosene with hydrogen.

- In a global aircraft/infrastructure approach, ALTEN teams are working to improve aerodynamic performance and optimize flight and airport operations through the SARAA project (Smart Avionics: Road to Autonomy by ALTEN); their work on on-board pilot assistance systems will reduce air transport CO2 emissions by 30%, paving the way for the evolution towards autonomous aircraft.

- The use of predictive and prescriptive maintenance has extended the life of cutting tools in the aerospace industry by up to 30%, drastically reducing costs.

Come to discover the mini plant on the ALTEN Chalet, lane B site no. 397