Digital transformation in nuclear: balancing performance, safety and sovereignty

Digital transformation is not a passing trend in the nuclear sector; it contributes to simplifying operational processes through the implementation of high-performance tools and to leveraging data, all while meeting stringent operational and regulatory requirements. In the context of industrial revival and skills renewal to support new builds and life extension of existing plants, an orderly and efficient digital transformation unlocks improvements in operational efficiency, asset performance, safety performance, and much-needed enhancements in security resilience as well as technological sovereignty.

Digitising a nuclear power plant is not a matter of improvisation. Every innovation must be qualified, traceable, and auditable – without ever compromising safety. Digital transformation in nuclear is therefore guided by a core principle: technological progress is only meaningful if it enhances control and system reliability.

A controlled, phased transformation

Digital transformation is not deployed uniformly. It is introduced in the lifecycle of the facilities:

- Design phase: digital tools accelerate modelling of complex systems through 1D, 2D, 3D, connected engineering tools, and digital twins. These hybrid models facilitate architecture validation and coordination among project stakeholders.

- Operations phase: connected technologies (IIoT, Edge Computing, AI) are transforming maintenance: beyond simply monitoring measurement points and process data, they give operators the ability to regain flexibility and operational margin as their plants age.

- Refuelling outages: the digitalisation of processes accelerates the industrialisation of preparatory phases and enhances outage management. It improves overall fleet performance and long-term replicability while strengthening the safety of operations.

This sequencing is deliberate, allowing innovation to be introduced at the right time while maintaining safety and regulatory compliance.

IT/OT convergence: the keystone of industrial digitalisation

The true technological turning point lies in IT/OT convergence – the integration of Information Technology (IT) and Operational Technology (OT). Historically segregated for security reasons, these two domains are beginning to communicate:

- Field data (temperature, vibration, pressure) feed a set of data models designed to improve reliability and predictability within facilities.

- Digital platforms centralise equipment supervision.

- Teams gain real-time visibility of plant performance and safety.

Yet this convergence also introduces new challenges. Opening OT systems to IT increases cyber risk exposure. Industrial cybersecurity has thus become a pillar of transformation, encompassing network segmentation, security-by-design architectures, sovereign perimeters, and reinforced software qualification.

Technological levers for performance

Nuclear digitalisation relies on a coherent set of technologies, all subject to rigorous validation requirements:

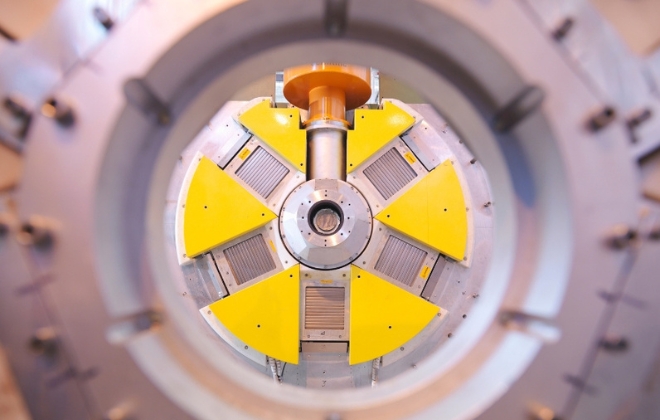

- Digital twins: Dynamic replicas of facilities, combining physical models and algorithms to simulate real-world behaviour. (Removed stray “High fidelity digital twin.”)

- Predictive maintenance: Detection of weak signals to anticipate failures weeks in advance.

- Digitalisation of operations and maintenance activities: Facilitating efficient and safe field activities and data-driven decision-making.

- Edge computing: Local processing of critical data, ensuring responsiveness and resilience if network access is lost.

- AI and low-code tools: Automation of documentation and generation of operational procedures based on existing knowledge.

These innovations do not replace human expertise; they augment it. The aim is not to dematerialise knowledge, but to capitalise, secure, and transmit it.

Human and sovereign considerations

A major challenge lies in preserving technical knowledge. Digital transformation becomes a lever for skill retention and transfer through shared knowledge bases, structured and data-driven documentation, and augmented reality training.

It also strengthens digital sovereignty: local data hosting, on-premises platforms, hybrid approaches, encryption, and model governance ensure control over information – a concern as strategic as safety itself.

ALTEN x Worldgrid expertise

Through Worldgrid, part of the ALTEN Group, engineers support European nuclear operators throughout this transformation:

- Defining digital roadmaps aligned with nuclear industry-recognised standards.

- Integrating qualified and secure I&C solutions.

- Industrialising hybrid digital twins for predictive maintenance and high-fidelity simulation.

- Designing and deploying digital tools for power plant operations and maintenance activities.

- Deploying Edge and sovereign modules for cybersecurity and operational continuity.

These projects embody a shared vision: safer, more efficient, and sustainable nuclear operations, where digital transformation accelerates mastery and trust.

Towards augmented nuclear operations

Digital is not a rupture, but a controlled continuity. By combining engineering, data, and cybersecurity, nuclear digital transformation prepares for an augmented future, where technical performance, safety, and sovereignty mutually reinforce one another.

Aeronautics

Aeronautics