Nuclear Safety, Lifetime Extension of the Existing Fleet and Enhanced Field Operations

Maintaining Operational Excellence in an Ageing Fleet

Nuclear power remains a strategic pillar of electricity generation in France and across Europe. As demand for low-carbon electricity continues to grow, extending and optimising the existing nuclear fleet has become a major challenge, essential to safeguarding energy sovereignty while upholding the highest standards of nuclear safety and security.

France currently operates one of the world’s largest nuclear fleets, with 57 reactors, half of which have reached or exceeded 40 years of service. To maintain their performance and reliability over time, EDF has launched ambitious engineering programmes such as the Grand Carénage, encompassing renovation, equipment replacement, integration of post-Fukushima measures, and improvements to the overall safety level of nuclear power plants. These operations mobilise thousands of engineers and specialised technicians, the guarantors of uncompromising safety.

In this context, the nuclear sector combines technological innovation, industrial mastery and risk management. Engineering plays a central role in anticipating failures, extending operational lifetimes, and securing interventions, all while taking into account regulatory and environmental constraints.

Ensuring Safety: An Absolute Imperative

Nuclear safety rests on a fundamental principle: preventing any incident that could endanger people, the environment, or the installations themselves. For a fleet that has been in operation for several decades, this imperative translates into heightened vigilance at every stage of the equipment lifecycle: monitoring component condition, ensuring full traceability of interventions, and guaranteeing technical reliability under all circumstances.

Specialist engineers conduct in-depth risk analyses, model failure scenarios, and verify the compliance of critical systems. These activities rely on probabilistic safety assessments, reliability studies and multiphysics simulations designed to anticipate extreme situations. Under the supervision of the ASNR (French Nuclear Safety Authority), regulations require continuous demonstration of the robustness and compliance of installations, even under accidental scenarios.

Alongside EDF, ALTEN plays an active role in controlling and demonstrating the technical compliance of French nuclear power plants. Since 2018, the Group has led the implementation of the fleet’s technical inspections, carried out Technical Conformity Examinations (ECOT), and drafted compliance monitoring programmes. These missions demand exemplary methodological rigour, founded on traceability, documentation quality, and mastery of regulatory requirements.

Extending the Lifetime of the Existing Fleet

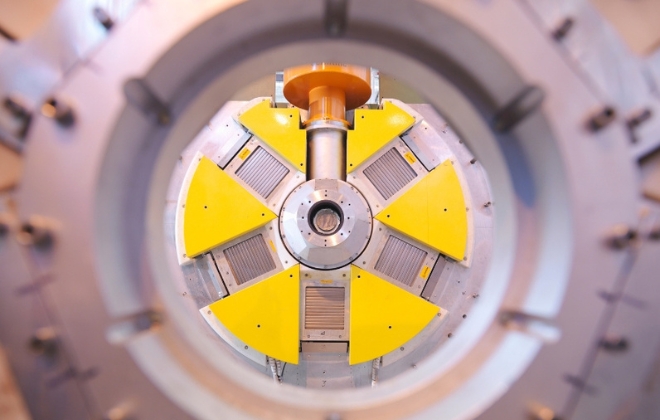

Extending the operation of reactors beyond forty years represents a major industrial and technological challenge. Mechanical, electrical, electronic, and civil engineering components are subjected to high stresses (temperature, pressure, irradiation, mechanical cycles, humidity, etc.) that fluctuate through repeated operating cycles. Addressing these challenges relies on multidisciplinary expertise, combining materials science, structural analysis, and non-destructive testing.

Ten-year inspection programmes (VD4 and forthcoming VD5) enable facilities to be requalified for an additional decade, taking into account regulatory evolutions, particularly in the field of safety. Engineers are involved throughout the lifecycle: reliability analysis, compliance studies, design modification management, and commissioning support.

Since 2018, ALTEN has supported EDF in preparing and producing the Operational Lifetime Extension Dossiers (DAPE), which are essential to the safety demonstrations presented to the ASNR. These dossiers, reassessed every ten years, are based on complex technical studies and a thorough command of the regulatory framework.

In parallel, the Group contributes its expertise to modernisation and new reactor programmes, notably the EPR2 projects, providing know-how in systems engineering, instrumentation and control, and configuration management. This complementarity between extending the existing fleet and developing new generation units gives ALTEN a comprehensive and integrated vision of the nuclear sector’s safety and performance challenges.

Enhancing Field Operations Through Digital Technology and AI

On-site interventions are critical moments for nuclear safety. Every operation, whether maintenance, inspection, modification, or equipment replacement, must be meticulously prepared, executed, and documented.

Digital tools and artificial intelligence are transforming these practices: digital supervision, immersive simulation, and digital twins allow teams to prepare interventions under near-real conditions. These technologies reduce human error, minimise downtime, and optimise team coordination.

Leveraging data from sensors and control systems paves the way for predictive maintenance, enabling early detection of anomalies, anticipation of failures, and prioritisation of critical operations.

ALTEN’s Added Value for its Clients

ALTEN’s approach is rooted in the conviction that nuclear safety and industrial performance are inseparable. The Group mobilises its multidisciplinary expertise in systems engineering, data, AI, project management and document control to support clients at every stage of the installation lifecycle

This integrated approach enables:

- A comprehensive view of risks and better management of interfaces between disciplines;

- Continuous optimisation of operation and maintenance processes;

- Full traceability of technical data, essential for regulatory compliance;

- Sustainable improvement in worker safety and operational reliability.

Aeronautics

Aeronautics