Smart your engines

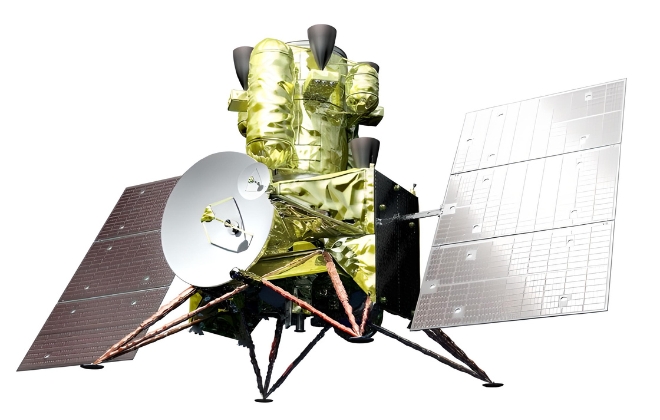

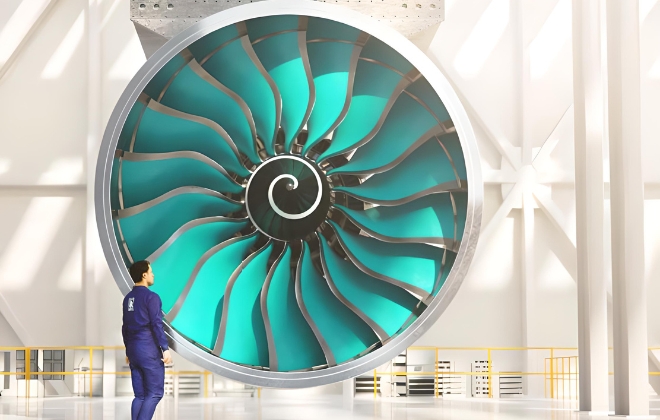

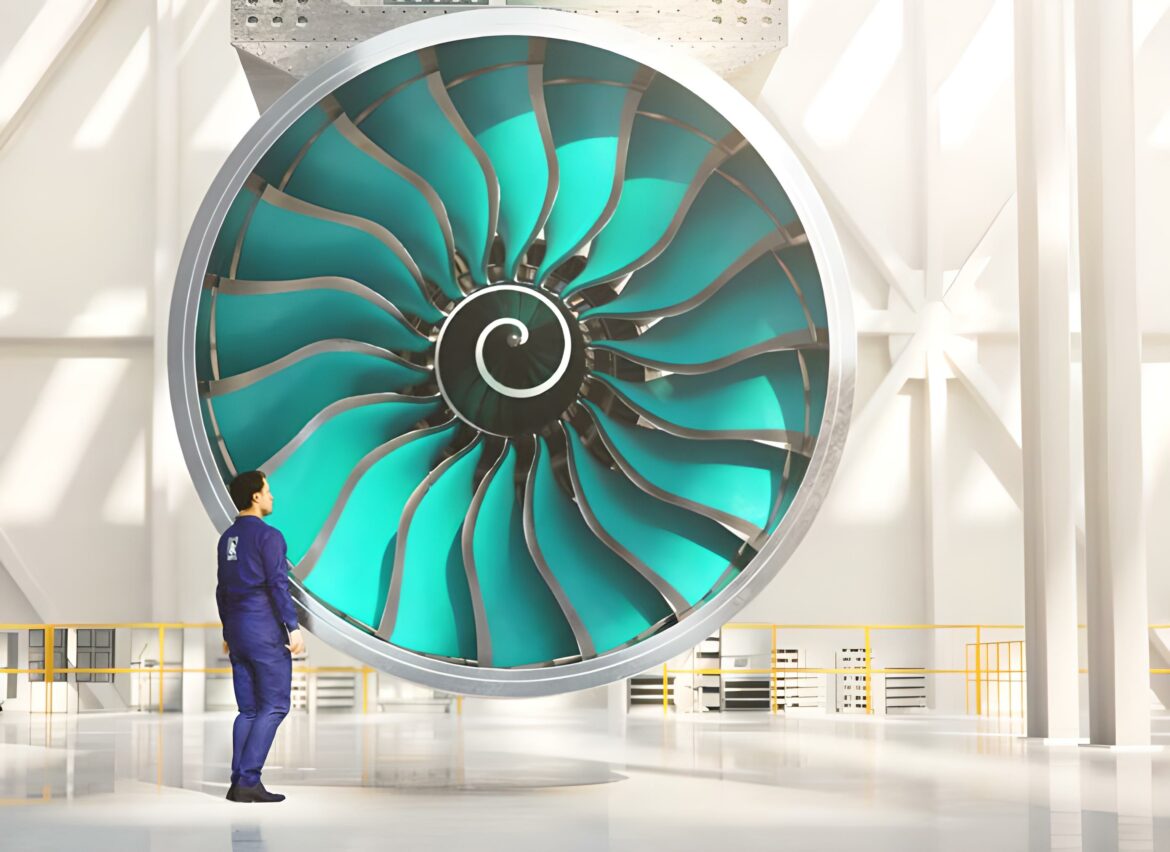

ALTEN customer is one of the world’s largest commercial aircraft engine manufacturers. While the company also has activities in defense, power systems, energy, and civil aerospace – building engines for planes like the Airbus A350 or the Boeing 787– is their main market.

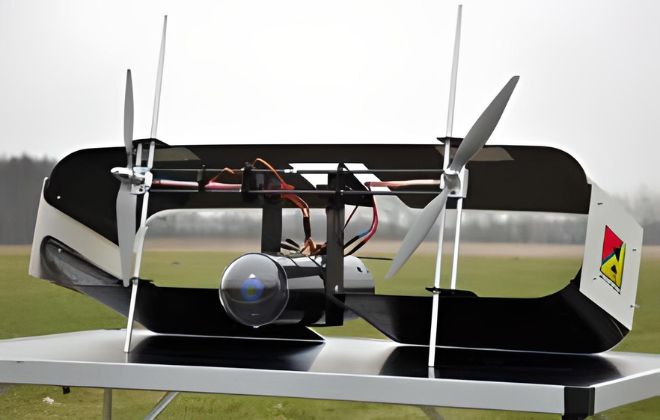

This British aero-engines manufacturer is at the forefront of today’s industry challenges, continuously innovating and making significant strides towards enhancing efficiency, minimizing noise and fuel consumption of their engines. The company knows that the right partnerships are key to face those challenges and so they began working with ALTEN in 2017 on the recommendation of Airbus, benefiting from their ability to provide fast ramp-up in engine deliveries. As the market focuses on the roadmap to NetZero by 2050, exploring electrification, sustainable aviation fuel and hydrogen to power planes, ALTEN, as a strategic partner, plays an active part in building tomorrow’s aviation.

From provider to partner

As Covid restrictions eased at the end of 2021, the airline industry needed to get back on track quickly. For this company, this meant meeting the double demands of burgeoning air traffic and reaching the global objective of net-zero by 2050. To meet the backlog in demand for aircraft engines, the gas turbines manufacturer decided to revaluate their relationships with engineering services providers, rationalizing their supply chain and reducing their panel of subcontractors to a few, selected partners. ALTEN, already a successful collaborator, brought multidisciplinary skills to the table – from designing new components to certification and customer service – that help ensure end-to-end business success.

Over time, ALTEN extended its offering to this key aerospace player with offsite activities in the UK and Germany, and later offshoring in India. This enables the customer to benefit from significant cost savings while maintaining a strong front office, high quality delivery and customer relationships. More than 800 ALTEN experts work on projects for this British aero-engines manufacturer, which have grown to include areas such as systems and software, design and integration, development and testing, as well as aftermarket support.

To meet the demand for greener aircraft, this customer also found that ALTEN, with more than 4,200 aeronautical engineers in 15 countries, could lend important research and development support. ALTEN’s experience in cryogenics and management of hydrogen at very low temperatures, as well as in the exacting mechanical and thermal analysis required to ensure the integrity of these tanks, were a deciding plus in ongoing research to produce hydrogen-powered planes.

A valuable partnership

Cost optimization

ALTEN’s contribution to this aerospace key player goes beyond providing engineering services. One crucial aspect is cost optimization. ALTEN excels in delivering complex projects on time and on quality, thanks to its dedicated proven delivery framework. Through productivity initiatives and streamlining of operations ALTEN has successfully enabled this customer to save over 1 million USD in direct costs in just one year. Moreover, ALTEN’s offshore model plays a key role in achieving cost efficiencies.

Skills development

ALTEN’s commitment to skill development is demonstrated through its centers of excellence, which bring together teams with specialized knowledge and expertise in specific technical areas. These centers, offer comprehensive training programs and inductions for new employees, ensuring they quickly acquire the necessary skills and knowledge. In 2021 alone, over 500 engineers went through the Aero-Engines Centre of Excellence, then delivering on this customer projects and further enhancing their skills.

Innovation

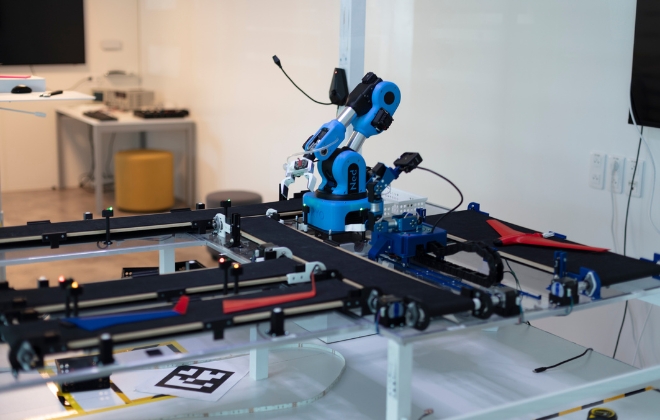

Innovation is a central pillar of ALTEN’s strategy, exemplified by the establishment of ALTEN Labs, innovation centers located worldwide. These Labs act as digital enablers, leveraging AI and Data Science technologies to tackle engineering challenges and develop innovative solutions. An excellent example is the Derby innovation center in the United Kingdom, where new automation and digital tools were created for this British aero-engines manufacturer in 2021. These tools have enabled them to save thousands of work hours annually, fostering increased efficiency and productivity.

By excelling in cost optimization, investing in skills development, and driving innovation through ALTEN Labs, ALTEN consistently goes above and beyond to support its customers’ engineering needs. Their collaborative efforts have resulted in significant cost savings, enhanced skillsets, and game-changing solutions that contribute to the continued success of this customer in the industry.